Related Products

What is the principle of woodworking machinery?

The working principle of woodworking machinery is a type of machinery that uses processing methods such as sawing, planing, turning, milling, drilling, etc. to process wood into wooden molds, wooden objects, and various utensils. It is a commonly used machinery in various enterprises. In addition to wood processing, it is commonly used in the wooden mold workshop (section) and auxiliary workshop (woodworking workshop) of casting branches (workshops) in mechanical manufacturing plants. Due to the status of woodworking production in mechanical manufacturing plants, woodworking machinery and its operational safety often do not receive the necessary attention.

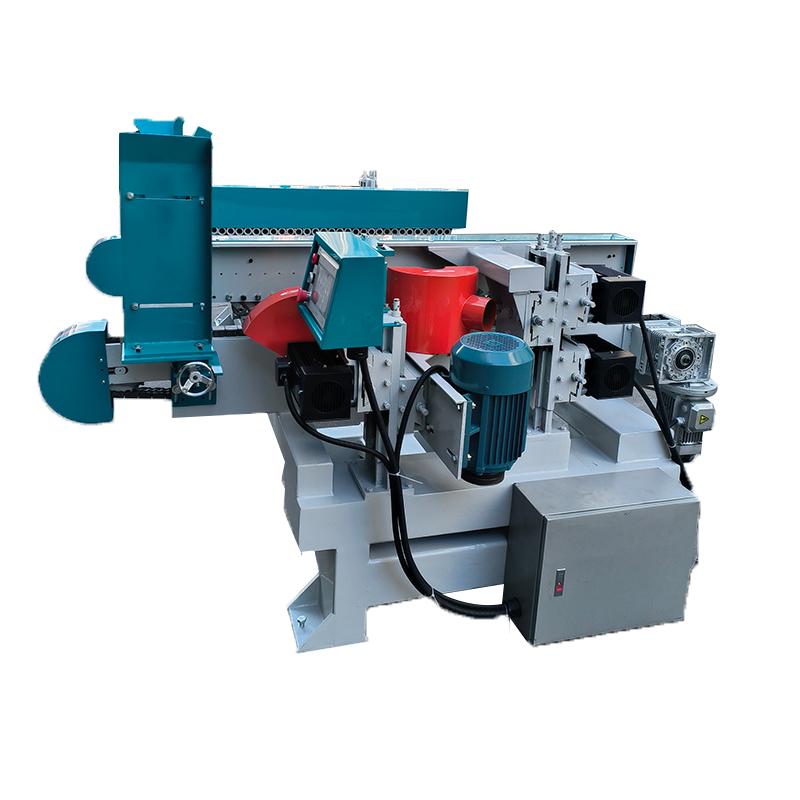

Woodworking machinery can be classified into the following categories based on the working principle, structural performance characteristics, and scope of use of the equipment:

(1) Woodworking sawing machines can be divided into longitudinal circular sawing machines, transverse circular sawing machines, band sawing machines, reciprocating sawing machines, chain sawing machines, and saw board machines based on the motion characteristics, basic structure, and layout of the workpiece and cutting tools.

(2) Woodworking planers include single sided, two sided, three sided, four sided planers, and flat planers.

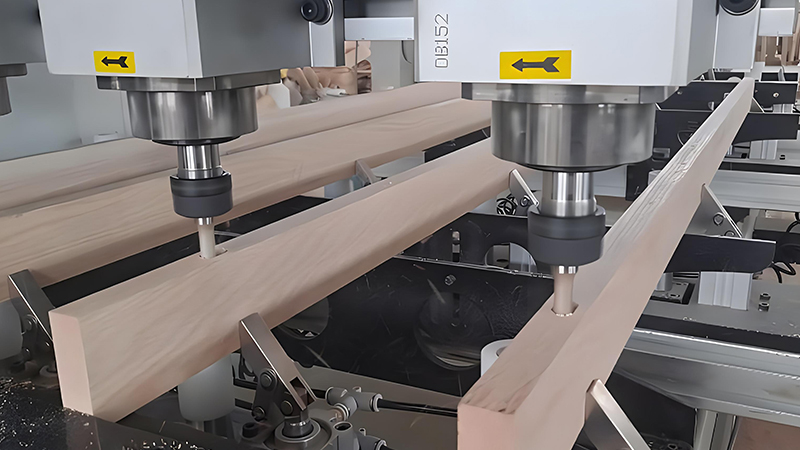

(3) Woodworking milling machines include interface milling machines, vertical milling machines, double-sided, three sided, four sided milling machines, and profile milling machines.

(4) Woodworking drilling machines include vertical single axis, multi axis drilling machines, horizontal drilling machines, multi axis row drilling machines, and specialized drilling machines.

(5) Woodworking tenoning machines include horizontal, chain, and ordinary tenoning machines.

(6) Woodworking lathe

(7) Woodworking shell machines include disc type, narrowband type, drum type, combined polishing machine, and broadband sanding machine.

(8) Woodworking multi-purpose machine tools include planing machine combination machines, planing machine combination machines, and sawing machine combination machines.