Related Products

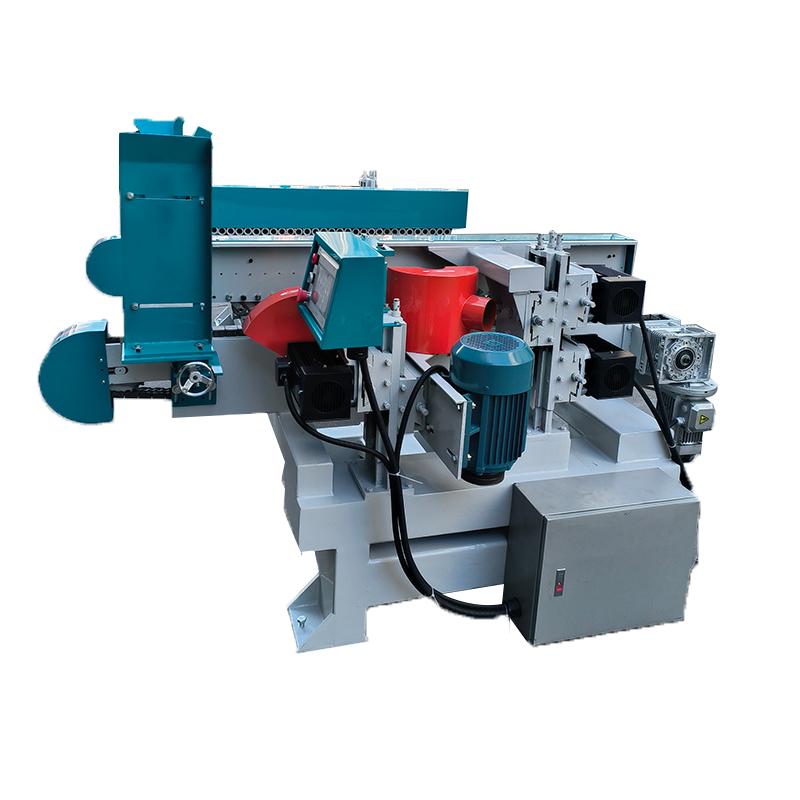

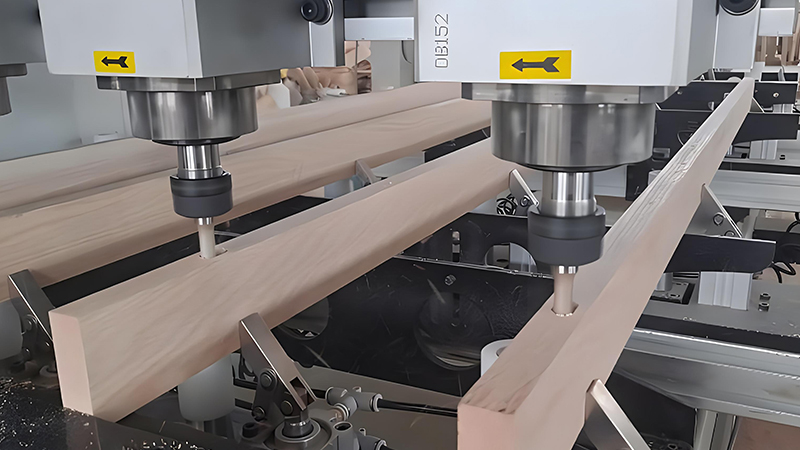

Suitable workplaces for woodworking equipment

(1) All processes that use toxic, irritating, and flammable substances should be placed in separate factories or arranged in specially separated areas within the factory, and equipped with personal protective equipment and firefighting equipment.

(2) The passage for transporting logs, sawn timber, and waste in the workshop should be equipped with and eliminate ventilation facilities such as corridors, foyers, door curtains, curtains, etc., as well as facilities to prevent fire spread such as automatic fire doors, fire and smoke dampers, water curtains, etc.

(3) When it is necessary to safely reach the work position above the equipment in the workshop, an overpass with protective railings and stairs should be installed. Anti slip flooring should be installed on the factory floor and overpass passages.

(4) There should be no equipment or lines on commonly used pedestrian walkways. Their width should not be less than 1 meter

(5) The conveyor belt below the ground should be covered with a cover plate or a grid shaped protective plate. The surface of the metal plate should be non slip. The gap width of grid protection shall not exceed 30mm

(6) Sawdust and waste storage tanks should be placed outside the factory building.

When the noise level exceeds the national standard, noise reduction measures should be taken in the building and layout.

(1) A ceiling made of sound-absorbing material (slag cotton sound-absorbing board) should be installed in a large factory building with a height of 6m. If the width of a tall and long factory building is less than the height, sound-absorbing panels should also be installed on the walls on both sides.

(2) When the height of the factory exceeds 6m, install sound-absorbing suspended ceilings above the woodworking machine tools.

(3) If the noise level of woodworking machine tools installed in the factory is very high and remote operation is allowed, operators can work in the soundproof room.

(4) By appropriately arranging various equipment according to the different noise intensities of woodworking machine tools, the goal of reducing noise levels can also be achieved. The equipment with the highest noise, such as planers, circular saws, and band saws, should be arranged separately from other equipment