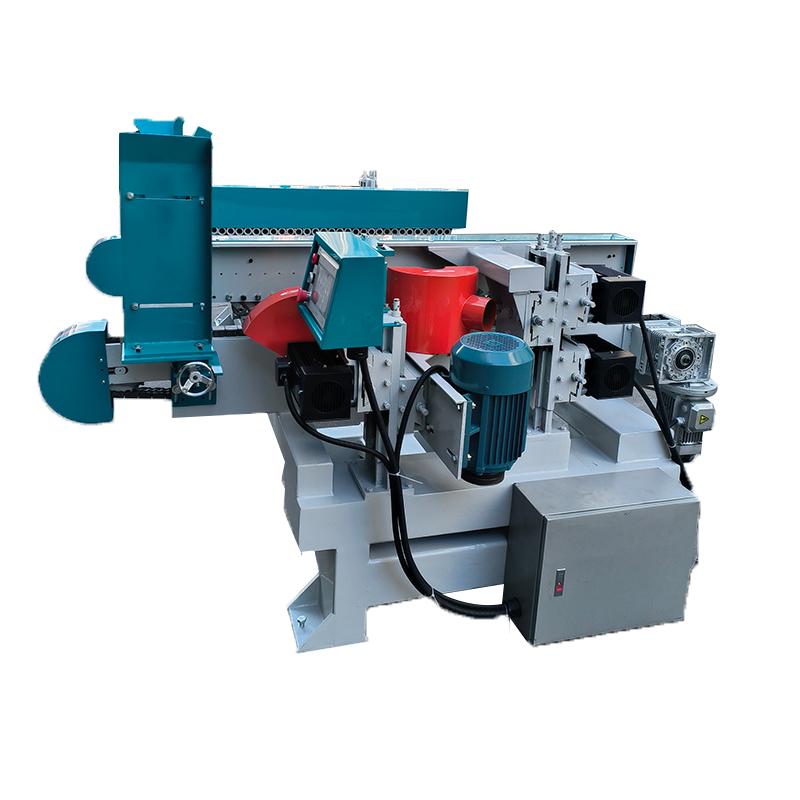

Related Products

Key points for monitoring the safe use of woodworking machinery

(1) Mechanical operators should wear tight fitting clothes and long hair, and are not allowed to tie ties or wear gloves.

(2) The installation and removal of mechanical power supply and the troubleshooting of mechanical electrical faults should be carried out by professional electricians. Machinery should use one-way switches, and reverse and two-way switches are not allowed.

(3) Mechanical safety devices should be complete and effective, protective covers should be installed on the transmission parts, and all components should be connected tightly

(4) Mechanical workplaces should be equipped with complete and reliable fire-fighting equipment. Smoking and hot work are prohibited in the workplace, and other flammable and explosive materials are not allowed to be mixed together.

(5) The wood in the workplace should be neatly stacked and the roads should be unobstructed.

(6) Machinery should be kept clean and no debris should be placed on the workbench.

⑦ The installation of high-speed rotating components such as pulleys, saw wheels, blade shafts, saw blades, and grinding wheels in machinery should be balanced.

(8) The degree of damage to various cutting tools shall not exceed the requirements specified in the user manual.

(9) Before processing, metal objects such as nails and wires should be removed from the wood

(10) Before installing a dust removal device on woodworking machinery, the dust removal device should be started first, and the dust removal pipeline should not be deformed or leak air

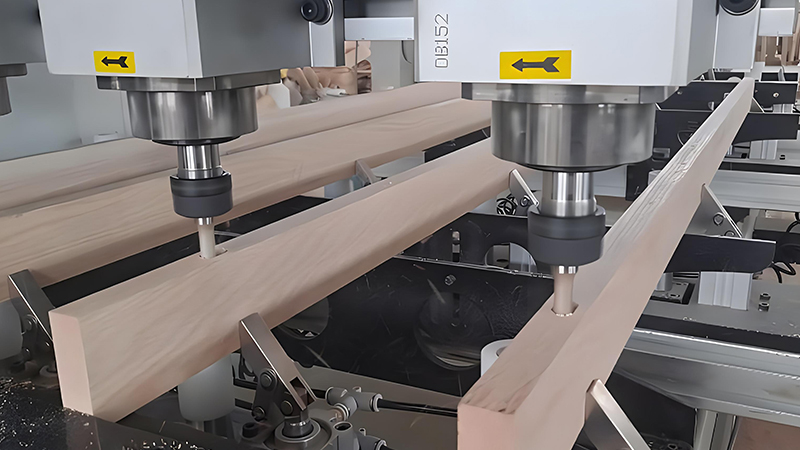

Previous: Usage of tenoning machine

Next: No More