Related Products

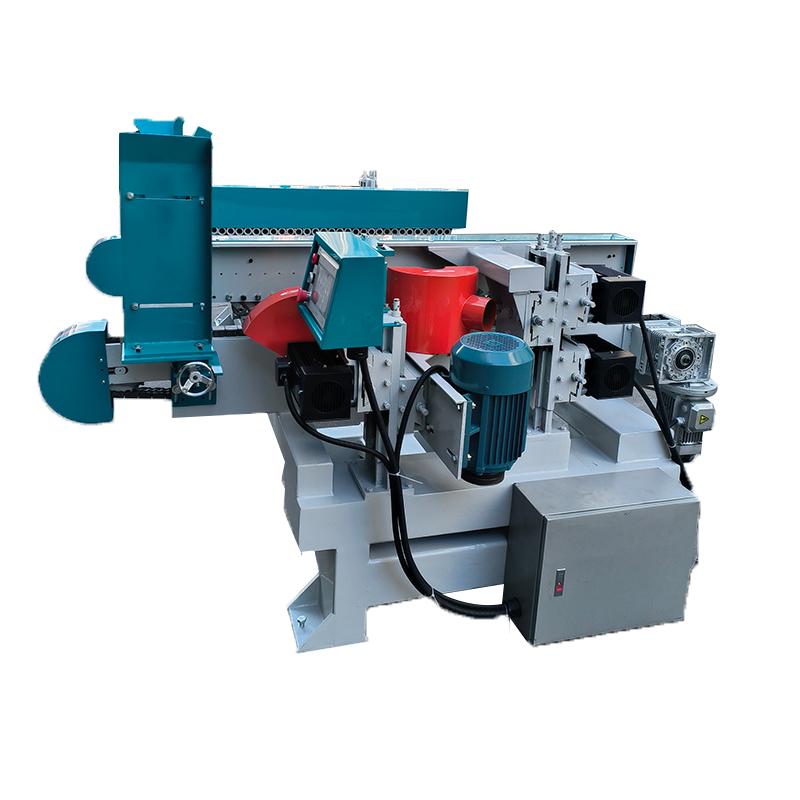

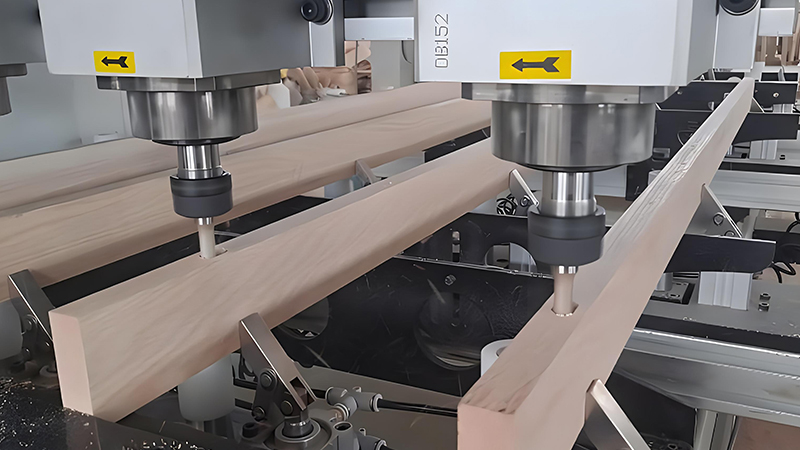

Usage of tenoning machine

Drilling through holes: If it is necessary to drill through all at once, a wooden block should be added under the workpiece; If the thickness of the workpiece is greater than the length of the drill bit, it should be drilled from both sides of the workpiece.

Drill half hole: The workbench needs to be raised to the required height before drilling.

Drill long holes: Move the worktable left and right to the desired position by rotating the longitudinal feed handwheel on the table.

Drill slanted holes: Use a mold with a slope to fix the workpiece for processing.

Multi hole drilling: For workpieces with small hole spacing, after each hole is drilled, the longitudinal feed handwheel of the workbench can be rotated to move it left or right by one hole spacing before drilling; For workpieces with large hole spacing, the press should be released and the workpiece should be moved to the drilling position before clamping for drilling.

Drilling and milling mortises: Ensure that the shape of the mortises is neat, not inclined, and that the edges of the holes are flat without misalignment or sawdust.